About us

Our history

1960

A new mill in Syktyvkar was expected to become the biggest mill in the USSR and Europe. The high bank of the Vychegda River near the Sloboda Settlement was chosen as its future location.

1963

In 1963, the grand construction of the largest USSR pulp & paper mill was started in the taiga on the bank of the Vychegda River. Thousands of volunteers from all over the union arrived to participate in this top-priority soviet construction project.

1966

Mill’s Power Plant was build within three and a half years, which was an unbelievably short term for the time. The first stage (1966 -1969) covered the construction of two bark boilers, three gas boilers, two soda recovery boilers, and five turbines. The design capacity of the Power Plant equaled to 194k kW.

June 25, 1969

On June 25, State Committee signed an Acceptance Certificate for SLPK’s first process line and board machine start-up. This day is now commemorated as mill’s anniversary.

1970

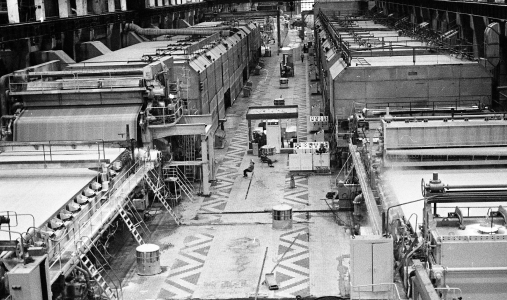

Startup of Paper Machine 1 (today’s PM 11) marked up the beginning of papermaking at SLPK. The machine was manufactured by Swedish KMW, and the initial product was printing paper. Nowadays PM 11 produces offset paper.

1982

PM 14 was built by Valmet, and at first it produced printing paper. Later PM was repurposed for offset and office paper following the market changes. Today PM 14 makes the famous Snegurochka and office paper of other brands.

1985

PM 15 is the “youngest” paper machine at SLPK (Voith make). Newsprint is the main product of this paper machine. Running on TMP/CTMP and not on pulp is a feature of PM15.

1999

Cut-Size Line construction was driven by the launch of a novelty product for the mill, i.e. office paper. Entering new markets demanded both high quality parameters and proper product appearance, and the latter directly depends on cutting and packaging quality.

2002

The Mill joined Mondi Group, an international producer of paper and packaging.

2007

SLPK stopped using elemental chlorine in pulp bleaching and put an emphasis on green technologies.

2008

SLPK expected to increase its capacities and logging volumes, thus its investment into post-harvesting reforestation became a logical and forward-looking step. The Forest Nursery grows viable containerized pine and spruce seedlings with survivability rate of almost 100%.

2010

STEP was the biggest investment project in the Russian pulp & paper industry of the time. This enormous rebuild resulted in a huge increase of production capacities and a significant improvement of environmental figures. The investment amounted to € 545 million.

2012

A new large-format cut-size line with an automatic wrapper allowed to boost the capacities and to widen the product range both in size and grammage.

2014

The startup of the pulp dryer enabled production of dry softwood market pulp, a new product made of controllable certified wood by chlorine-free method.

2019

Large-scale upgrade of SLPK waste water treatment facilities and implementation of best available technologies enabled a raise of waste water treatment quality and equipment efficiency.

2020

The project covered installation of a new bark boiler, a steam turbine, and an upgrade of distribution networks. These actions allowed to process the whole volume of the bark wastes, and to increase Power Plant’s green energy generation up to 40%. Yearly CO2 emissions were reduced by more than 200 000.

2021

Horizon investment roadmap embraced upgrade of the fiberline, pulp dryer, installation of pulp storage towers for 6 and 10 thousand cubic meters, installation of a tall oil plant, and construction of an additional railway on the mill premises. Implementation of these actions magnified the efficiency and improved workflow of various mill departments, enabling maximum use of mill potential.

2023

OOO Sezar Invest takes ownership of the Mill